Technical support

Our enthusiasm and enterprising attitude to achieve product technology leadership, and to provide customers with comprehensive support.

Service is a culture and has been integrated into our corporate culture. It is a system and procedure that is accepted and followed by all our employees.

Technology and quality strength

In addition to innovation ability, also focus on technical strength and quality strength, seeking excellent technical partners in various fields to jointly develop more competitive products, a number of professional quality engineers technical support. Every product goes through a laboratory quality test before it goes on the market.

Let consumer electronics enrich people's lives

However, with the gradual expansion of the market and the iterative updating of products, the original simple products are difficult to meet the needs of the majority of users, and timely transformation is imminent. Step into the 3.0 era, start to layout new product lines, open a diversified development model.

Brand terminal image store

To the interior layout, the overall style is simple and stylish. High-quality product quality, excellent product design, good use experience, so that the brand image store is welcomed by the majority of users, the momentum of vigorous development makes the products quickly spread throughout the domestic and foreign markets.

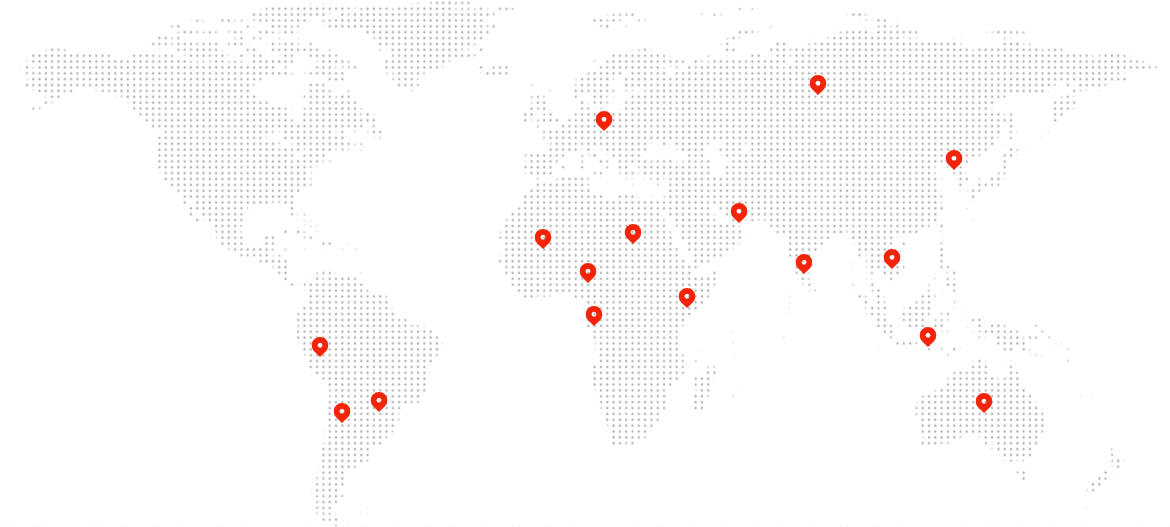

Network layout

Yisuo takes fast service 100% as its brand positioning, continuously optimizes and upgrades various fast service measures, builds scientific fast service process and advanced information management platform to achieve standardized and systematic customer service management, and strives to create a full range of one-stop solution services for customers before, during and after sales.

Q&A

In this section, you will find some of the most common questions and answers about various products

- The material moves irregularly

In the process of using a sewing machine to sew clothes, sometimes there is an irregular phenomenon of uneven movement speed and short stitch time. The cloth is moved forward by the matching of the cloth teeth and the press foot, so when the cloth appears the above irregular movement, it can be concluded that the teeth and the press foot are faulty or the pressure is improperly adjusted. For example, the press foot pressure is too small. If you don't press the fabric tight, you'll have an irregular movement. At this time, just turn the pressure screw downward to press the material. The presser foot is too high to hold the material, which will also cause the material to move arbitrarily, or not move at all. When adjusting, lift the presser foot wrench, loosen the guide screw, and then move the presser foot rod from top to bottom, so that the distance between the presser foot and the pin board is adjusted to a height of 7-8 mm, and then tighten the screw and then use the car.

There is also a reason that the teeth screws are loose, which causes the teeth to shake left and right when running, so that the clothes can not move forward regularly. The treatment method is to remove the needle plate. Tighten the two tooth screws. After tightening, install the needle plate, check both sides of the teeth, whether there is friction with the edge of the needle plate slot, if there is friction, it will cause noise and machine heavy phenomenon, then only remove the needle plate, loosen the tooth screws, adjust the tooth position to the middle of the needle plate slot, tighten the tooth screws, and then install the needle plate.

- The cloth does not move forward

The cloth is moved by the teeth. When it appears that the material does not move at all, only in the teeth to find fault. If the teeth are too low, the material cannot move forward. When adjusting, first pull up the machine head, loosen the screw of the tooth lifting crank, and then gently lift the tooth holder with a screwdriver to make the cloth teeth aligned. It is enough to expose the needle board 0.8-1 mm. It is the standard size of the tooth height, as long as it is adjusted to this position, the cloth can move normally. Tighten the screws. While turning the screws. Turn the nose up again.

- The cloth goes back and forth

When sewing clothes, there will often be clothes walking back and forth, that is, one step forward and one step back. This is caused by the high feeding teeth, the plane of the teeth exposed to the needle board is too high, and the teeth are always exposed to the reciprocating movement outside the needle board, resulting in the clothing moving back and forth. When adjusting, loosen the crank screw for lifting the teeth, gently press the teeth downward with a screwdriver, and reduce the feeding teeth to the standard height, that is, the tooth is exposed to the size of 0.8-1 mm of the needle plate, and then tighten the crank screw.

- The cloth receded

In the sewing work, sometimes the material does not move forward, but moves in the direction of the operator, that is, the material moves backward. This fault is caused by the wrong Angle between the upper shaft crank and the CAM eccentric screw. So the teeth move forward rhythmically. It all depends on the toggle of the cloth feed CAM. Because the CAM itself is eccentric. Therefore, the fork moves back and forth, and the fork drives the cloth shaft and the tooth holder to promote the teeth to move back and forth. It can be seen that the eccentric position of the CAM is very important.

Standard Angle between upper shaft crank and CAM screw. As long as the Angle between the CAM screw and the upper shaft crank is adjusted to 260-300, the material will not retreat.

When adjusting, pull the back cover of the machine head down, you can see the cloth feeding CAM, insert the screwdriver into the interior of the case, loosen the screw of the cloth feeding CAM, and then turn the screw to the position of 260-300 with the upper shaft bend, and then tighten the CAM screw.

- Why is there no movement after my home electric sewing machine comes online?

First, make sure your home electric sewing machine is plugged in and switched on. Second, check whether the line is properly connected and whether the line is not broken or misaligned. Finally, check to see if the correct wires are plugged in. If the problem still does not solve, it is recommended to consult a professional maintenance personnel.

- Why do the needles of my home electric sewing machine often break?

There are several possible causes for a broken needle. First, check whether the needle is too old or has worn out, if so, it needs to be replaced in time. Second, take care to use the right needle type and size, as different fabrics and sewing projects require different needles. In addition, when sewing to maintain the appropriate speed, to avoid too fast or too slow, so as not to cause damage to the needle.

- How do I adjust thread tension on my home electric sewing machine?

Adjustment of thread tension There is usually an adjustment button on the top or side of a household electric sewing machine, which can be turned to increase or reduce thread tension. Depending on the type of thread you use and the thickness of the fabric, adjusting the right thread tension can make sewing smoother.

- My home electric sewing machine needle and thread often knot, how to solve?

Knotting problems can be caused by the thread not going through the lead channel or thread buckle of the sewing machine correctly. Check that the lead channel and cable tie are correct and ensure that the cable ends pass smoothly. In addition, maintaining proper thread tension and stable sewing speed can also reduce the probability of knot.

- How to maintain a household electric sewing machine?

Regular cleaning of a household electric sewing machine is an important step in maintaining its normal working condition. You can use a clean cloth and some sewing machine cleaning solution or alcohol to wipe down the body and thread to remove dust and fibers. In addition, it is also necessary to apply an appropriate amount of oil regularly to keep the machine lubricated.

简体中文

简体中文 English

English España

España